LED modules are widely used products among LED products. They form modules with specific functions by arranging and packaging LEDs in specific rules.There are many different ways to package LED modules, each with its own unique characteristics and applicable scenarios. The following are some common LED module packaging methods:

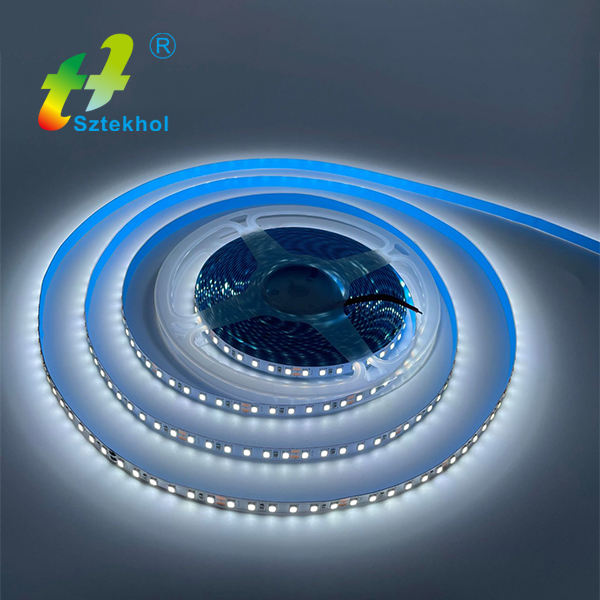

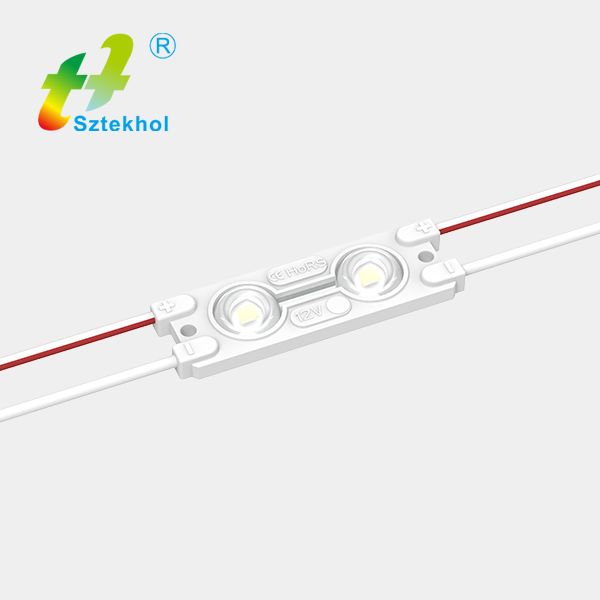

SMD packaging: SMD is the abbreviation of Surface Mounted Devices, which means surface mount devices. The SMD packaging method is to package the LED chip into lamp beads, and then solder the lamp beads on the PCB board to make LED modules with different spacings. SMD packaging technology is widely used in LED display screens, with the advantages of good heat dissipation, low production cost, mature and stable process. At the same time, the SMD packaging method is also suitable for the dot pitch range of P2-P10, which can meet the needs of different application scenarios.

GOB packaging: GOB is the abbreviation of Glue On Board, which is a packaging technology launched to solve the protection problem of LED lamps. GOB packaging uses an advanced new transparent material to encapsulate the substrate and its LED packaging unit to form effective protection. This packaging method has high protection, such as moisture-proof, waterproof, dust-proof, impact-proof, etc., and can be applied to more harsh environments. However, GOB packaging also has some problems, such as stress release, heat dissipation and colloid adhesion.

COB packaging: COB stands for Chip On Board, which means chip on board packaging. This packaging method is to attach multiple LED bare chips directly to the PCB board, and then completely seal the entire module. The COB packaging method eliminates the need for a bracket, making the process simpler. A single packaging structure can contain a large number of pixels, further reducing the dot pitch. At the same time, the COB packaging method also has the advantages of displaying a grainless picture and a softer and clearer picture. In the era of Mini LED and Micro LED, COB packaging has become one of the most suitable technical routes.

There are many ways to package LED modules, each with its own unique characteristics and applicable scenarios. When choosing a packaging method, it is necessary to comprehensively consider factors such as actual application requirements, cost budget, and technical difficulty.