Today, I will share the characteristics and advantages of LED injection molding module with friends.

The inherent characteristics of LED injection molding module determine that it is the most ideal light source to replace the traditional light source, it has a wide range of uses.

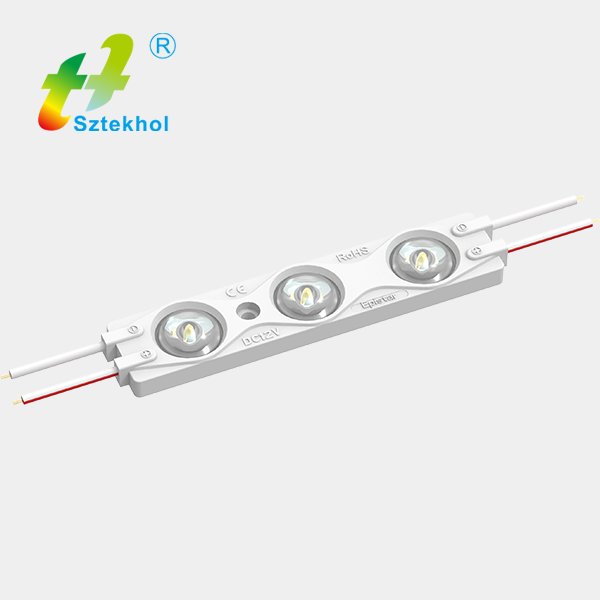

Small volume

It basically a very small chip encased in epoxy resin, so it’s very small and very light.

Low power consumption

Module Generally, the operating voltage of LED injection molding module is 2-3.6V. The operating current is 0.02-0.03A. That is it consumes no more than 0.1W of electricity.Low voltage input, safe and reliable use;

Long service life

With the right current and voltage, the life of the LED injection molding module is up to 100,000 hours

High brightness, low heat, environmental protection

LED injection molds module are made of non-toxic materials, unlike fluorescent lamps, which cause pollution by containing silver, and they can also be recycled.

Strong and durable

The LED module is completely ENC ased in epoxy resin, which is stronger than light bulbs and fluorescent tubes. There are also no loose parts in the body of the lamp, which makes the LED injection mold unbreakable.

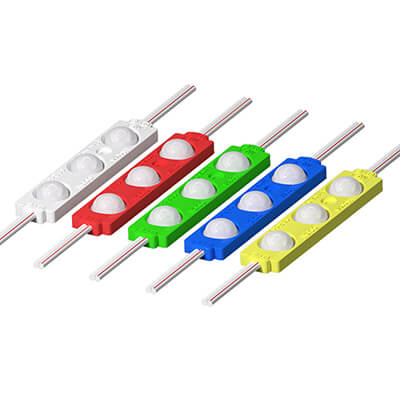

Can show red, blue, purple, green, yellow, green, white seven colors, seven color jump, seven color gradient, colorful jump, colorful gradient effect;

Light source selected TOP 2835 led, no light spot, low light decay, good consistency;

Low power consumption, high brightness, long service life, maintenance free;

The shell adopts injection molding process, beautiful appearance, unique, good heat dissipation effect;

Waterproof grade can reach IP65 or more;

20 modules for a string, LED series and hybrid circuit, a single module can be cut.

Come and send an inquiry