LED neon strip fabrication involves the manufacturing process of creating LED strips that mimic the appearance of traditional neon lights. neon flex supplier, durable, and energy-efficient alternatives to traditional glass neon lights. Here is an overview of the LED neon strip fabrication process:

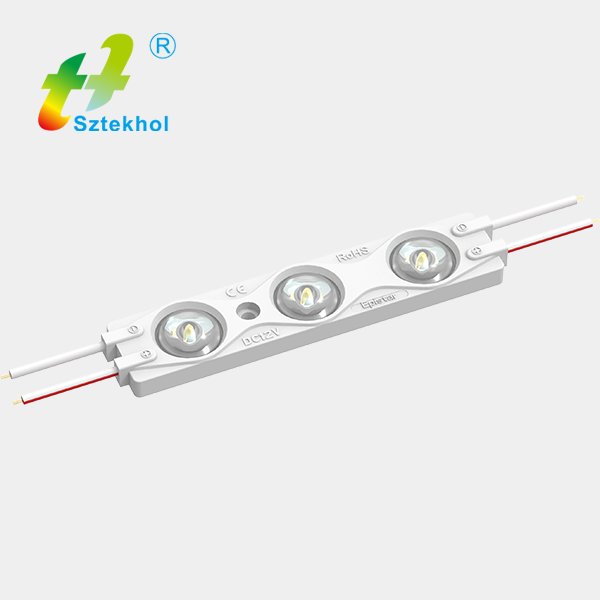

1. LED Chip Selection: The fabrication process starts with selecting high-quality LED chips. LED chips are the individual light-emitting components that produce the light in LED neon strips.

2. PCB Design: The design includes the layout of the LED chips, electrical connections, and any additional components required for controlling the LED strip.

3. Soldering: The LED chips are soldered onto the PCB according to the design layout. Soldering ensures a secure and reliable electrical connection between the LED chips and the PCB. The soldering process requires precision and attention to detail to ensure the proper functioning of the LED neon strip.

4. Encapsulation: After soldering the LED chips, the PCB is encapsulated with a protective material. This material shields the LED chips from external elements such as moisture, dust, and impact. The encapsulation material also helps in diffusing the light emitted by the LED chips, creating a smooth and even illumination.

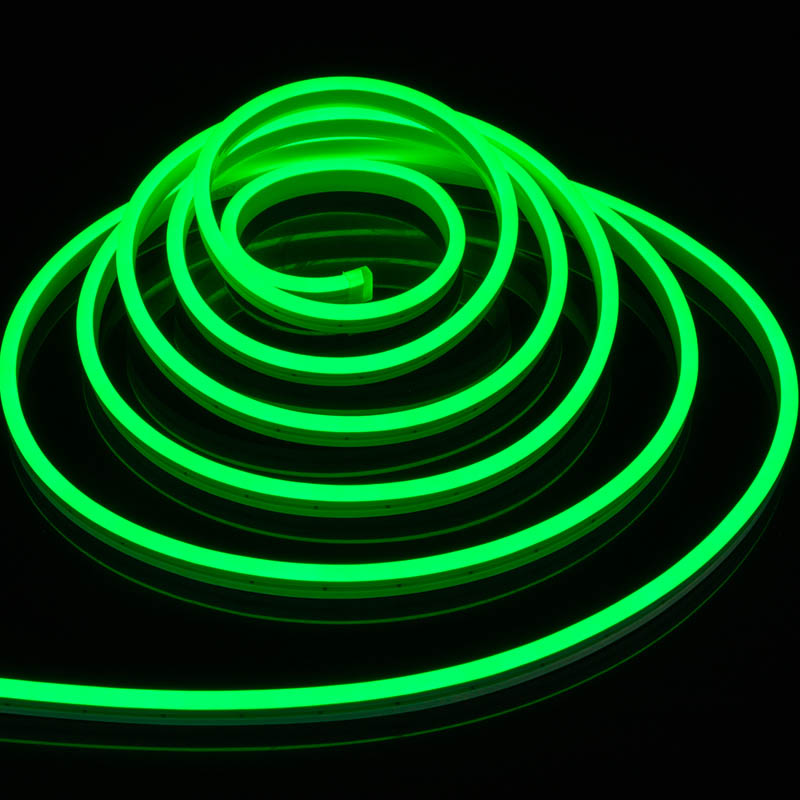

5. Outer Casing: LED neon strips often feature a flexible outer casing that mimics the appearance of traditional glass neon tubes. This casing is typically made of a durable and UV-resistant material such as silicone or PVC. The outer casing provides additional protection to the LED neon strip and allows for flexibility and easy installation.

6. Wiring and Connectors: The LED neon strip is equipped with wiring and connectors for power supply and control. These components enable the LED neon strip to be connected to a power source and controlled using dimmers, controllers, or other control systems.

7. Quality Control: Throughout the fabrication process, quality control measures are implemented to ensure that the LED neon strips meet the desired standards. This includes testing the electrical connections, checking for any defects or inconsistencies, and verifying the overall performance of the LED neon strip.

8. Packaging: Once the LED neon strips pass the quality control tests, they are packaged and prepared for distribution. The packaging ensures the safe transportation and storage of the LED neon strips until they reach the end users.

led neon supplier requires expertise in electronics, lighting technology, and manufacturing processes.