First, the production process

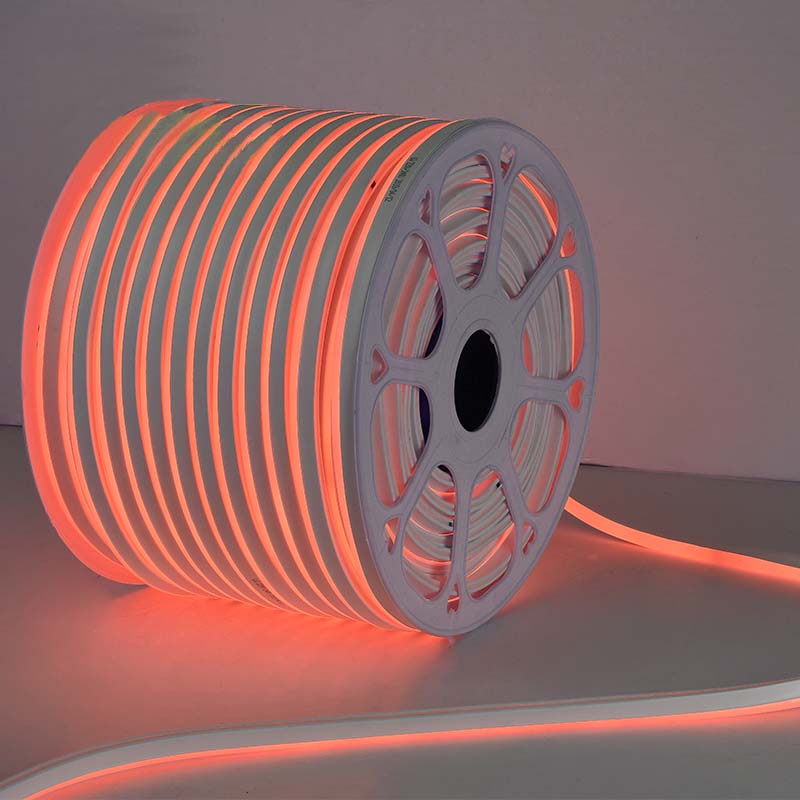

Integrated neon light: the light source strip and the silicone light guide tube are integrated and inseparable. LED light source strip and silica gel are extruded from the silicone machine to form a co-extruded LED flexible neon strip. This process will paste the lamp strip on the surface of the plate or shallow slot, there are many kinds of plates to choose, such as aluminum plate, stainless steel plate, PVC plate, acrylic plate and so on.

Split neon: The silicone light guide and the LED light source are separate. In the production process, the first slot on the board (commonly used PS board or PVC Chevron board), and then paste the S-shaped lamp strip in the slot, weld the wire and connect the various lamp strips, and finally cover the silicone strip to complete the production.

Second, material selection

Integrated neon: Because the lamp belt and silicone co-extrusion molding, the material choice is relatively flexible, and the bottom plate can be thick or thin, and the applicable plate types are more.

Split neon lights: S-type lights generally use a single-layer circuit board to bend horizontally; The thickness of the bottom plate is generally not less than 6mm to ensure the stability of the structure.

Three, the use effect

Luminous effect: Both can produce bright, vivid luminous effect, but the all-in-one neon lamp may be more advantageous in luminous uniformity and continuity, because its lamp belt is closely combined with silicone, reducing the scattering and loss of light.

Durability: The all-in-one neon lamp is more durable because the lamp belt is wrapped in silicone, which has better water, dust and weather resistance. Split neon lights may have potential leakage or loosening problems at the junction of the silicone strip and the lamp strip.

Safety: Integrated neon lights are safer during use because the LED strip is wrapped in silicone, which reduces the risk of exposed circuits. If the split neon lamp is improperly installed or long-term use leads to the loosening of the silicone strip, it may increase the risk of short circuit and fire.

Four, application scenarios

Integrated neon: due to its excellent durability, luminous effect and safety, it is more suitable for outdoor building lighting engineering, scenic landmark outline, commercial entertainment venue atmosphere decoration and other scenes that need to run for a long time and high security.

Split neon: although it has a certain luminous effect and flexibility, due to its durability and safety is relatively poor, it is more suitable for interior decoration, advertising signs and other scenes with low waterproof, dustproof and weather resistance requirements.